| |

|

150

YEARS OF INDUSTRIAL EXPERIENCE AT YOUR SERVICE

CHEVAL FRERES S.A., located in Besancon, the capital of

Micromechanics in France, is the leading French manufacturer

of YAG industrial lasers.

It was after developing its own laser sources for its traditional

watch-making business that CHEVAL decided to offer its customers

all of its 150 years at the service of industry. |

Laser

applications are numerous today: welding, cutting, drilling,

surface and deep marking.

CHEVAL marking laser have become essential tools for our customers,

keys to their success in today's fierce industrial competition.

|

|

|

CHEVAL

MARKING LASERS:

A CUSTOM-DESIGNED INDUSTRIAL SOLUTION

CHEVAL

offers an industrial solution perfectly adapted to each application.

We offer our customers an engineering department comprising 8 people,

equipped with high-performance CAD computer systems. Backed by many

years of experience in laser technology, a team of engineers and technicians

study and design the laser equipment which best suits the required

solution. The equipment meets CE standards in design and safety. Each

machine is delivered with a Certificate of Conformity. |

|

|

|

CHEVAL

MARKING LASERS:

FOR HIGH TRACEABILITY SPEEDS

Thanks to their

high level of flexibility, CHEVAL lasers integrate into and adapt

to the very high speeds of automatic production lines. The displacement

speeds of the laser beam allow 240 characters to be engraved per second.

The traceability speeds can therefore reach 24,000 parts/hour for

dating, in static or dynamic marking. The interfaces of CHEVAL lasers

dialogue easily with production line computer stations, electronic

labelling systems (Modas, Balogh etc.), traditional, binary and digital

bar codes, Data Matrix. In addition, our computer specialists design,

at our customers' request, "operator" interfaces which facilitate

the Man/Machine dialogue and cut down on series changing times.

|

|

CHEVAL

MARKING LASERS:

THE FLEXIBILITY OF A MEDIUM-SIZED COMPANY

The combination

of the customer's knowledge of the products he wishes to have marked

and our know-how in lasers and in the manufacturing of industrial

environments enables us to draft the job specifications and a technical

file together with our customers, thus guaranteeing the success of

the laser marking investment project. The flexibility of being a medium-sized

company enables us to have an open approach to the large diversity

of problems posed. Our active participation in the design and development

of our customers' new products is carried out with total discretion

and in accordance with a contractual confidentiality protocol. |

|

|

|

CHEVAL

MARKING LASERS:

DAILY INNOVATION

In order to innovate

in industrial applications, the laser department is equipped with

10 machines which are at the disposal of our customers. This allows

us to carry out all the required feasibility studies so we can choose

the most appropriate technical solutions. |

|

|

|

|

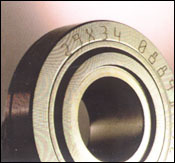

DETERIORATION-PROOF

MARKINGS:

The CHEVAL marking

laser makes deterioration-proof, high-quality markings on all kinds

of material. The marking can be surface or deep, depending on the

laser employed. The coloration of the steel surface can be white

or black according to the customer's choice.

FROM

JEWLLERY TO CAR INDUSTRY:

The industrial

applications are vast. From the identification of the Megane an Kangoo

vehicles from the car-maker RENAULT to the signature of DUPONT pens

or BOUCHERON jewels, our design engineers work in perfect harmony

with our customers. CHEVAL laser equipment, designed for outstanding

durability, not only affix our customer's signatures and guarantee

deterioration-proof traceability markings according to the standards

in force; they also cut down on the risks of imitations. |

|

DETERIORATION-PROOF

MARKINGS:

The CHEVAL marking

laser makes deterioration-proof, high-quality markings on all kinds

of material. The marking can be surface or deep, depending on the

laser employed. The coloration of the steel surface can be white or

black according to the customer's choice. |

|

|

|

NO

STRESS OR DEFORMATION OF THE PART:

CHEVAL marking equipment can be utilized on the most diverse shapes

of parts, with no need for specific mounting tools. No stress or deformation

is exerted on the part. As is often the case for surgical instruments

or in aviation, a series of markings can be programmed on several

axes of the laser equipment (axes X-Y-Z-C are programmable). Ceramics,

like other materials used in the medical field, can be engraved. The

markings resist to even the most severe sterilization methods.

|

|

STATIC

OR DYNAMIC MARKING:

Thanks to the rapidity of the CHEVAL lasers, the marking can be effected

in static mode, often used for sharp tools, due to the large variety

of references in low volumes, or in dynamic mode, e.g. for cutlery.

The marking of 1D bars codes (39- 2/5 -128) or 2D bar codes (Date

Matrix - ECO) directly on the part eliminates the need for labels

and ensures deterioration-proof traceability. |

|

|

|

WE

HAVE A SOLUTION FOR EVERY PRODUCTION LINE

From the most simple, manual operation machine to the multiaxis numerised

or robotised machine, the CHEVAL engineering department can offer

you customised solutions for your specific application. All our equipment

is ergonomically designed to provide ideal comfort for the operator.

The integration of the marking laser into the production line is effortless,

thanks to the dialogue of our programs with the customer's automatic

environment. |

|

HIGH

SPEEDS:

In order to eliminate idle loading and unloading time and to

increase speed, CHEVAL FRERES offers transfer systems. According

to the positioning precision required and to the volume of the

parts to be marked, our engineering department offers you different

solutions: linear transfers or rotary tables. CHEVAL rotary

tables ensure a high level of repeatability of precision in

the positioning of parts. The quality of the material meets

the requirements of the most severe speeds in the car-making

field for weekly work in five shifts. These rotary tables are

not limited to two positions and numerous possibilities are

offered for integrating other equipment in each position.

|

|

|

|

|

EQUIPMENT

AUTONOMY:

CHEVAL equipment can be fitted with X/Y crossed table transfer systems

which provide the equipment with a certain amount of autonomy. The

part loaders are anchored on the crossed table and processed automatically.

The focal distance may be managed by a numerised Z axis. The marking

of a vernier can be carried out over 360° through the utilization

of a rotating numerised axis. In order to increase the autonomy of

this equipment, a vertical conveyor with built-in pallets can be added.

In this case, each pallet is identified by a label for the choice

of the marking program of the parts positioned on each pallet. |

|

UNFALSIFIABLE

MARKINGS:

UP TO 0.35 MM OF DEPTH ON STEEL The CHEVAL pulsed YAG laser, essential

in the car-making field, engraves a 7 mm high character per second

at a depth of 0.35 mm on steel; this ensures unfalsifiable marking.

This equipment comprises a portable head connected to a laser source

by an optic fibre. Little influence of the length of the optic fibre

is observed on the quality of the beam. A suction system built into

the portable head recycles the steel dust and smoke of sheets coated

with paint or oil. The noise level of this equipment is lower than

75 dBA. Control of the text to be engraved is automatic, via reading

of bar codes, of Balogh or Modas labels. |

|